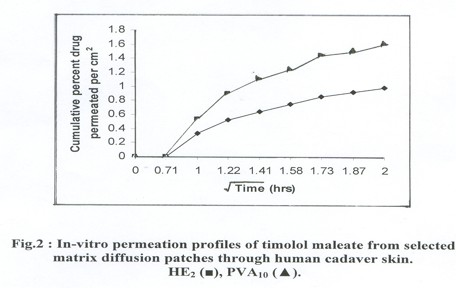

The permeation profile of drug from both patches HE2 and PVA10 when plotted,between permeation data against square root of time shows linear relationship indicating drug permeation followed Higuhi equation (Fig.2).

Saraf Swarnlata*, Saraf S1, and Dixit V.K. 2

1Institute of Pharmacy, Pt. Ravishankar Shukla University, Raipur (CG) 492 010

2Department of Pharmaceutical Sciences, Dr. H.S. Gour V.V., Sagar, M.P.

*e-mail: swarnlata_saraf@rediffmail.com

Summary

Transdermal delivery of timolol meliate was tried for both reservoir as well

as matrix system. The physically stable patches regarding drug contents, tensile

strength, toughness and WVT were found for PVA10 and HE2 formulation. Both patches

follows diffusion controlled drug permeation and high permeation with PVA10

while reservoir system follows zero order permeation kinetics.

Introduction

Timolol maleate is a beta adrenoceptor-blocking agent used in treatment of cardiovascular

diseases like myocardial infarction, angina pectoris, hypertension, respiratory

complications and migraine. It is 8-10 times potent than propranolol 1. The

main limitation of therapeutic effectiveness of timolol maleate is its higher

frequency of drug dosing and short biological half-life, high first pass metabolism

and poor bioavailability by oral route. . It is rapidly absorbed from gastrointestinal

tract with peak plasma concentration of 5-10 ng/ ml after 1 hr2, it is metabolized

up to 80% in liver with a mean half-life of 2.0-2.5 hr.3, thus necessitating

frequent administration of larger doses to maintain therapeutic drug level.

Therefore, To maintain effective plasma concentration and to avoid sub therapeutic

and toxic concentration, a continuous delivery of timolol maleate is required.

The transdermal route is, therefore, a better alternative, to achieve constant

plasma level, which additionally warrants less frequent dose regime.

The present study has been selected transdermal delivery system to achieve maximum

therapeutic benefit.

MATERIALS AND METHODS

Gift sample of timolol maleate (TM) was obtained from Cadila Antibiotics Ltd.,

Ahamdabad. Hydroxy propyl methylcellulose was procured from Warner Hindustan

Ltd., Hyderabad. Dibutyl phthalate, ethyl cellulose, polyvinyl alcohol (PVA),

HEPES buffer, procured from Sigma Chemical Co. St. Locus Mo, USA. All other

chemicals and regent used were of analytical reagent grade.

Fabrication of matrix diffusion patches

Matrix patches were casted4 on mercury using stainless steel rings having inner

diameter of 1.5 cm and thickness 0.5 cm were used for holding the polymer solution

on mercury surface. Two type of polymer patches were prepared; HPMC and EC combination

and with PVA. The polymer solutions were prepared by dissolving HPMC 10% ands

EC 10 % separately in methanol- chloroform (1:1) mixture. Both solutions were

mixed together in combination of 1:9, 2:8, 3:7, 4:6 and 5:5 respectively using

1% dibutyl phthalate as plasticizer. A weighed amount of drug is dispersed in

polymer mixture then poured in ring placed on mercury surface in petri dish

at a uniform place and solvent evaporation was controlled by conveying with

funnel. After evaporation of the solvent, the film was taken out from the metal

ring by sharp knife and preserve in aluminum foil. Similar procedure was adopted

to prepare PVA matrix patch preparation having polymer concentration of 5, 10.and

15% in water with 0.5% glycerin as plasticizer.

Physical characterization

Thickness of polymeric patch was measured by using a dial gauge (Mercer, England),

having least count of 0.002 mm. To maintain its shape, enough hardness is required

to resist independence or penetration was determined by Hall’s method4

and calculated as a functional weight. In order to determine the elongation

as a tensile strength, the polymeric patch was pulled by means of a pulley system;

weights were gradually added to the pan to increase the pulling force till the

patch was broken. The elongation i.e. the distance traveled by the pointer before

break of the patch was noted with the help of magnifying glass on the graph

paper5, the tensile strength was calculated as kg/ cm2. The presence of moisture

may not affect the hardness of patch in the normal environmental conditions,

but it may affect in exaggerated conditions. The polymer patches were cut, weighed

and placed in a humidity chamber maintained at 68% RH for 72 h for equilibrium.

After 72 h polymer patch were taken out and weight accurately. The difference

between initial and final weight was computed as percentage moisture absorbed.

The water vapor transmission (WVT) from the film was calculated by Crowfold

and Esmeric formula 6. It was determined at 25+ 20C at 68%RH. Glass weighing

bottles of equal diameter (2.5 cm) and height (5.0 cm) were used as WVT cells.

A weight quantity of anhydrous calcium chloride was taken up to 10 mm height

in each cell and a thin layer of silicon adhesive grease applied over the brim

then patch was placed on brim and adhesive was allowed to set for 5 minutes.

The cells are accurately weighed and kept in humidity chamber maintained at

68% RH for 24 h. After 24 h, the cells were again weighed and an increase in

weight was considered as a quantitative measure of the moisture transmitted

through the patch. Drug distribution studies: The distribution of drug in polymer

patch effect the release rate. It was studied microscopically with the help

of Lietz Microscope to observe uniform distribution of drug in patch.

Stability studies:

Stability studies of all patches were performed at different storage condition

by measuring tensile strength, moisture content and drug content (spectrophotometric

method). The measurement were carried out by keeping the patches at different

conditions of temperature 280C, 350C and 500C and relative humidity of 30%,

50%, 68 % for storage period of three months at room temperature (25±10C).

The patches, which maintained uniformity, shape, toughness, drug content and

flexibility at all temperature and RH, were selected for further permeation

studies.

Skin Preparation:

The full thickness human cadaver skin was washed with purified water after removal

of all subcutaneous fat and hairs and cut in to pieces for experimental use.

The skin pieces were soaked in HEPES buffer and store in freezer at 300C until

used. Just before the experiment, it was thawed at room temperature and checked

for any microscopical damage.

In vitro drug permeation studies:

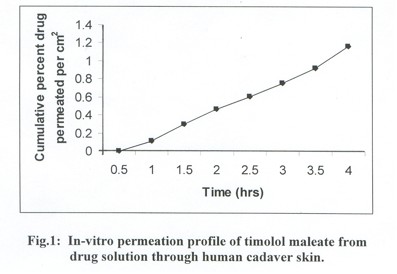

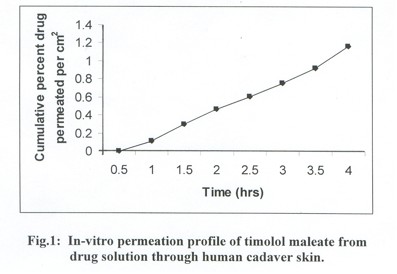

A drug permeation study was carried out with drug solution in HEPES buffer pH7.4

and stable patches through human cadaver skin using modified kieshry- chein

diffusion cells. The concentration of drug kept similar in drug solution in

HEPES buffer and patches to compare permeation profile. The Patches and drug

solution were kept on stratum cornium side of cells and this patch - skin -

complex sandwiched between donor and receptor compartment. The receiving compartment

contains blank 10.0 ml of HEPES buffer pH 7.4 and touches the dermal side of

the skin. The whole of the assembly was kept on magnetic stirrer, which thermostatically

controlled at 37+ 2oC at 100 rpm. Samples were withdrawn at pre set time interval

from the receiving compartment and analyzed spectrophotometrically at 294 nm

using shimadzu-1601 UV- visible spectrophotometer. The fresh buffer in receiving

compartment was replaced after each withdrawal. The permeation studies determined

for period of 4 h. and calculated as cumulative percent drug permeated.

Results

In present studies, the polymer and plasticizer choice for patch preparation

were based on no interaction with drug and HEPES buffer with considerable stability.

Various combinations of polymers hydroxy propyl methyl cellulose (HPMC) and

ethyl cellulose (EC) and various concentration of polyvinyl alcohol were tried

for patch preparation and evaluated for physical studies (Table 1).

| Formulation Code | Polymer Used | Polymer Core % w/v | Thickness Mm |

Hardness Gm/cm |

Tensile strength Kg/cm2 |

WVT gm/cm2 / 4 h |

Moisture absorption % |

| HE1 | HPMC:EC | 1:9 | 0.034 |

322 |

2.12 |

2.20 |

2.11 |

| HE2 | HPMC:EC | 2:8 | 0.036 | 314 |

2.98 |

2.63 |

2.43 |

| HE3 | HPMC:EC | 3:7 | 0.035 | 312 |

3.00 |

2.98 |

2.88 |

| HE4 | HPMC:EC | 4:6 | 0.035 | 306 |

3.51 |

3.23 |

3.03 |

| HE5 | HPMC:EC | 5:5 | 0.033 | 302 |

3.83 |

3.40 |

3.1 |

| P5 | PVA | 5.0 | 0.031 | 290 |

2.00 |

3.02 |

2.99 |

| P10 | PVA | 10 | 0.036 | 298 |

2.10 |

0.32 |

3.22 |

| P15 | PVA | 15 | 0.034 | 302 | 2.54 | 4.01 | 4.00 |

Table 1: Physical evaluation of polymeric patch of Timilol maleate

The main physical evaluations considered for stability were WVT rate, tensile strength and % moisture absorption and drug content. The polymer patch prepared with combination in the ratio of 2:8 HPMC and EC (HE2), PVA of 10% w/v (P10) were found to be satisfactory at all temperatures and relative humidity. On the basis of physical and stability studies, the patches HE2 and PVA10 were considered for permeation studies. The in- vitro permeation studies of drug solution and patches were performed to observe permeation profile. The permeation profile of both solution and patches were compared

Discussion

The in- vitro stability studies of all patches were performed in terms of stability

against storage conditions and aging effect, because TM is a drug used for long

therapy to maintain its therapeutic effect especially when used as antihypertensive

agent. The physical characterization like tensile strength, moisture absorption

and WVT rate and drug content were main parameter for stability studies, which

revealed no appreciable changes occurred in patches (HE2 & PVA10) at normal

storage conditions (250C+1). The drug solution permeation profile suggests that

it followed Fick’s law of diffusion. Linear relationship between cumulative

percent drug permeated verses time indicate zero order permeation of drug through

human cadaver skin with lag time 35 minutes. The transdermal permeability coefficient

of TM was calculated to be 323x10-5 +0.02cm2/h from the steady state portion

of the curve (Fig.1).

The permeation profile of drug from both patches HE2 and PVA10 when plotted,between

permeation data against square root of time shows linear relationship indicating

drug permeation followed Higuhi equation (Fig.2).

The permeation profile

data of patches were plotted in log values with time, the slope value comes

near to 0.49+0.01SD (~ 0.5), suggesting drug permeation is controlled by diffusion

within the matrix rather than by skin.

When we compare both patches, the PVA10 system provide higher 1.589 + 0.20 SD

% drug/ cm2 of permeation rather than HE2, i.e., 0.987 +0.20 % drug/ cm2 in

4h of period.

Conclusion

The studies suggest that

both reservoir as well as matrix system of transdermal delivery of TM is possible.

The reservoir system followed zero order while the matrix system followed first

order release profile. Among both matrix systems PVA10 patch have more permeability

than HE2 patch.

References

1. Napolian, L. A., Smith, R. L., Proceed. Int. Symp, Controlled Release Bioact.

Mater., 17, Controlled Released Society Inc. USA 1990, Abst. No. D220.

2. Remington Pharmaceutical Sciences, 18th Ed., Mark Publishing Company, Pennsylvania,

1990, P 1676.

3. Vermeji P. J,. Pharm. Pharmacol, 1978, 50,53.

4. Sciarria, J. J., Patel, S. P., J. Pharm. Sci., 1975, 64, 128.

5. Allen, D. J., DeHerco J. D., Kwan, K. C., J. Pharm. Sci., 1972, 61, 107.

6. Crawford, R. R., Esmerian, O. K., J. Pharm. Sci., 1971, 60, 314.

First Published February

4th 2006

All pages copyright ©Priory Lodge Education Ltd 1994-2006.